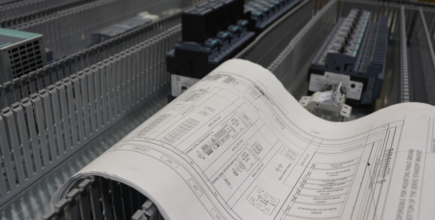

Navigating the Control Panel Landscape: Exploring Industry Standards and Regulations

ce, IEC, international electrotechnical commission, National Electrical Code, national electrical manufacturers association, nec, nema, quality assurance, ul 508A Adherence to industry standards and regulations is paramount. These guidelines ensure safety, reliability, and...Read More

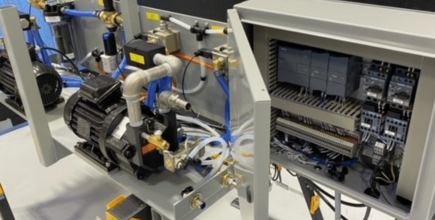

Crafting Excellence: Choosing the Perfect Materials for Your Control Panel Project

control panel assembly, corrosion resistance, cost-effective, custom enclosures, durability, electrical components, electrical wiring, flame-resistance, heat dissipation, nema, reliability, safety standards, thermal considerations, ul 508A In the world of control panel assembly, every component matters. One of the pivotal...Read More