Crafting Excellence: Choosing the Perfect Materials for Your Control Panel Project

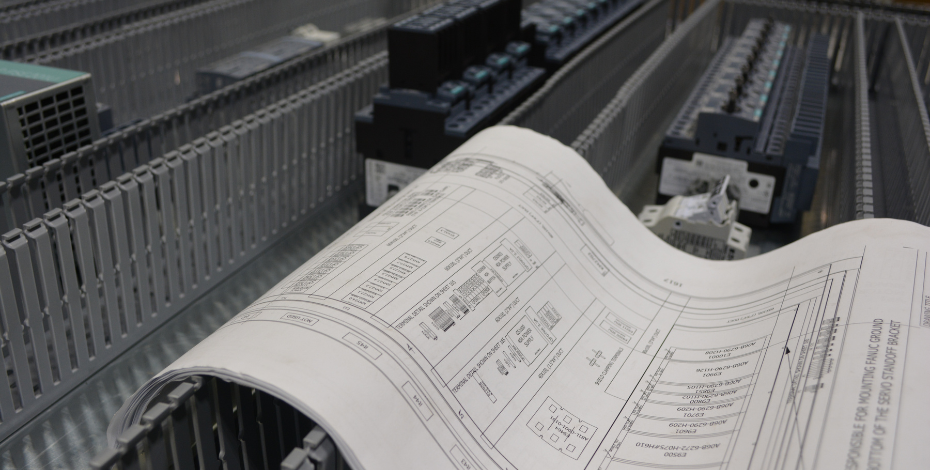

In the world of control panel assembly, every component matters. One of the pivotal decisions in creating a reliable and efficient control panel is selecting the right materials. As a leading control panel assembly company, MIS Controls understands that choosing materials is not just about functionality, but also about durability, safety, and performance. In this blog post, we shed light on the significance of material selection and guide you through the process of making the best choices for your control panel project.

Prioritizing Durability and Reliability

Control panels operate in a multitude of environments, from temperature-controlled rooms to harsh industrial settings. The materials used in their construction must withstand these conditions. When selecting materials, consider factors such as resistance to corrosion, moisture, chemicals, and UV radiation. At MIS Controls, we carefully assess each project’s requirements to ensure that the chosen materials deliver long-lasting durability and reliability.

Safety and Compliance

Safety is non-negotiable in control panel design. Selecting materials that meet industry safety standards is critical. Flame-resistant materials, for example, reduce fire hazards. Compliance with standards such as UL 508A and NEMA ratings ensures that your control panels are safe for operation and minimize risks to personnel and equipment.

Electrical and Thermal Properties

Control panels involve intricate wiring and electrical components. The chosen materials must have suitable electrical insulation properties to prevent short circuits or electrical malfunctions. Additionally, thermal considerations are vital. Heat dissipation properties of materials influence the control panel’s overall performance and lifespan. Optimal material selection helps in maintaining component efficiency and prevent overheating.

Customization and Adaptability

Every control panel project is unique, and the materials used should reflect this. Whether you require specific colors, custom enclosures, or unique mounting options, the chosen materials should accommodate these requirements. At MIS Controls, we provide tailored solutions by leveraging materials that align with your project’s specific needs.

Cost-Effectiveness and Sustainability

While quality is paramount, the cost-effectiveness of materials cannot be ignored. Opting for materials that strike a balance between quality and affordability is crucial for project viability. Additionally, sustainable materials contribute to environmentally responsible practices. Consider using recyclable and eco-friendly materials that align with your sustainability goals.

The MIS Controls Approach

At MIS Controls, we consider material selection as a foundational aspect of control panel assembly. Our experienced engineers meticulously assess project specifications, environmental factors, and compliance requirements to determine the ideal materials. From the enclosure to internal components, we ensure that each part is selected to create control panels that exceed expectations.

Conclusion

Choosing the right materials for your control panel project is a pivotal step in ensuring performance, safety, and longevity. The choices you make impact not only the panel’s functionality but also its reliability in demanding conditions. At MIS Controls, our commitment to excellence extends to every material we use. Whether you need custom solutions, compliance assurance, or innovative designs, we are your trusted partner in crafting control panels that stand the test of time. Contact us today to explore how our expertise in material selection can elevate your control panel projects to new heights of success.