Material Handling

& Process Control

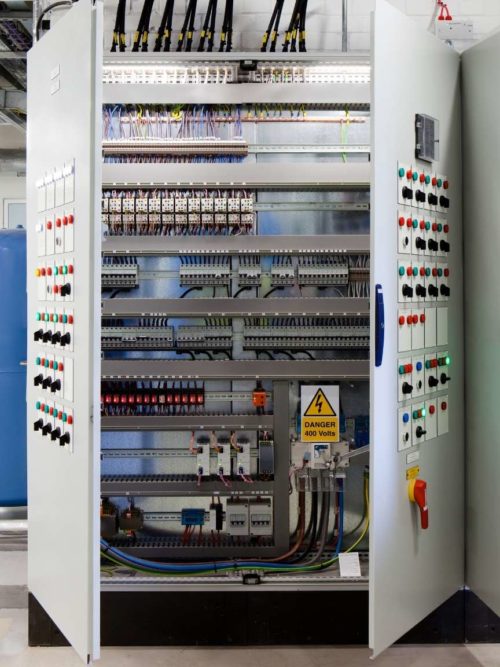

Material Handling incorporates many aspects of the industrial process. MIS Controls assembles systems that maintain the movement, protection, storage, and control of materials and products throughout manufacturing, warehousing, distribution, consumption, and disposal. As a process, material handling involves both semi-automated and automated equipment that require systems to make the supply chain work.

Process Control Systems (PCS), or Industrial Control Systems, act as equipment that monitors and gives feedback for troubleshooting purposes throughout the manufacturing process. Examples of PCS types include Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controllers (PLC), and Distributed Control Systems (DCS) that all process data while production continues. These systems monitor pressure, flow rate, force/torque, and temperature through various sensors. The automated nature of these systems is integral in the project management of complex assemblies.