Control Panel Categories

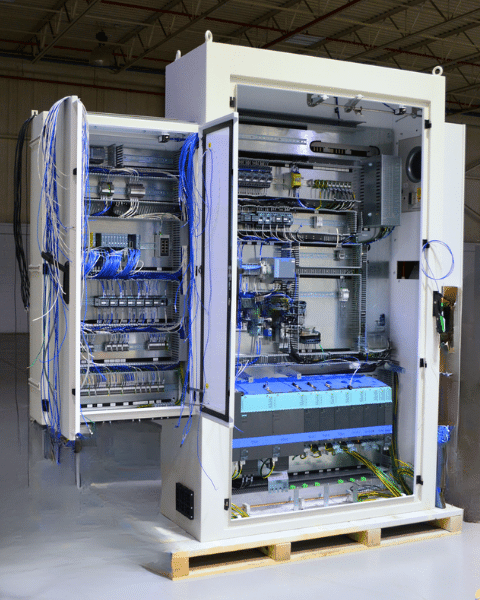

PLC Control Panels

Programmable Logic Controllers (PLC) are an integral part of any industrial control application. In short, they deliver intelligent, productive, and discrete architecture for many systems in the manufacturing process, motion applications, safety, and other process controls. For this reason, MIS Controls specializes in the assembly and integration process of any PLC controller into an Industrial Control Panel. Our expertise includes:

- Build-to-Print with Attention to Details

- All OEM Installation Requirements Established

- Low-to-High Volume Production Capabilities

- UL 508A Certified Approval Availability

HMI Control Panels

A Human-Machine Interface (HMI) is a dashboard that connects to a machine, device, or system. These interfaces allow people to engage and interact with any source machine application. Ideally, they are suited for mount integration into a complex machine. Specifically, with this application, they appear on mounting arms or as touchscreen workstations. With this in mind, MIS Controls provides the manufacturing of various HMI Controls. Our builds include:

- Build-to-Order and Custom HMI Applications

- Low-to-High Volume Production Capabilities

- Functional Testing On-Site

- On-Time Delivery Guaranteed

- UL 508A Certified Approval Availability

CNC Control Panels

Computer Numerical Control (CNC) Panels allow for automated control to establish highly productive and efficient applications. These panels are highly customizable, allowing for many different end uses. To emphasize this application, control panels for the machine tool industry are at the center of MIS Controls’ services and capabilities. All in all, you can rely on MIS Controls to manufacture the CNC Panel to the most stringent customer requirements and specifications. Our capabilities include:

- Full Production Capabilities

- All Customer Specifications Included

- High-End Performance Delivery

- UL 508A Certified Approval Availability

State of the Art Control Panels

State of the Art Panels use a variation of electric circuits to turn other devices into the same or different circuits. Moreover, Relay Control Panels come in various sizes and are easily customizable for any project size or scope. MIS Controls holds vast experience and expertise in the assembly manufacturing of various Relay Control Panel applications. Additionally, we perform complete functional testing of each Relay Panel to meet our customer requirements and industry standards. Our capabilities include:

- Project-Based, Custom Application

- Low-to-High Volume Production

- Complete Sourcing and Turnkey Solution

- Full Functional Testing to Customer Requirements