EV Battery Control Systems

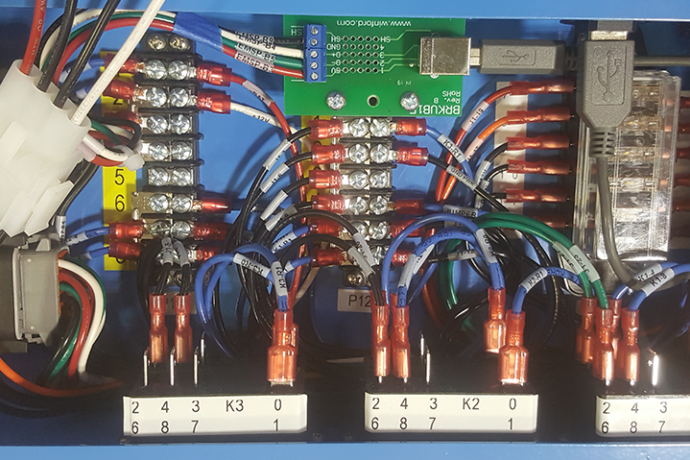

The Battery Monitor Control System regulates the lithium battery following the initial testing methods. Altogether, it contains:

- Current and Voltage Protection

- Thermal Management

- Digital and Analog Output Controls

- Intelligent Cell Balancing

- Health Monitoring

- State-of-Charge Monitoring with Drift

- Field-Programmable Features

These systems can be customizable to the exact scope of the given project. Overall, for any EV product, a form of monitoring must be present to stay informed on the inner workings of the innovative machine.

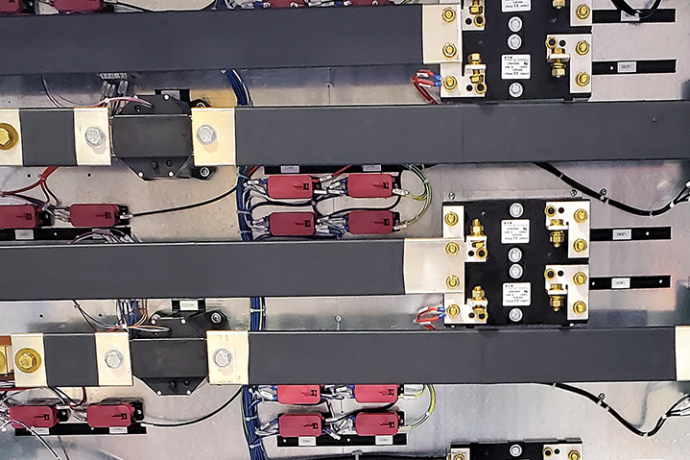

Safety increases with EV Contactors that regulate high-power machines. The details of the enclosure maintain the security of the electrical components.

- Suit well for several high-voltage applications

- Provide both safe connection and disconnection of the traction battery in hybrid, electric, and fuel cell vehicle

- Protect onboard charging systems

- Withstand heat, vibration, pressure, and other extremes

- Include custom bus bars for high functionality

1000V DC Contactors are in high demand for their high power. MIS assembles systems to maintain this intensity.

MIS specializes in using your engineer’s design to assemble new EV projects.

We have an advanced selection of capabilities and a manufacturing plan to handle every system. This selection includes:

- Compact EV Charging Systems

- Advanced, Custom EV Battery Testing Systems

- Panel Enclosures for EV Battery Storage

- Kiosk Assembly for EV Charging / Maintenance

By focusing on custom builds, our creative solutions lead to successful innovation. Any EV Project is safe in our hands!