Lithium Battery Monitor Control System

Challenge

Create a downsized, cost-effective computerized enclosure panel with fusing and relays to monitor Lithium battery units used in the material handling industry.

Application

Anderson Material Handling Lithium battery units, utilized in the material handling equipment, needed a custom enclosure computer monitor with a USB port.

MIS Solution

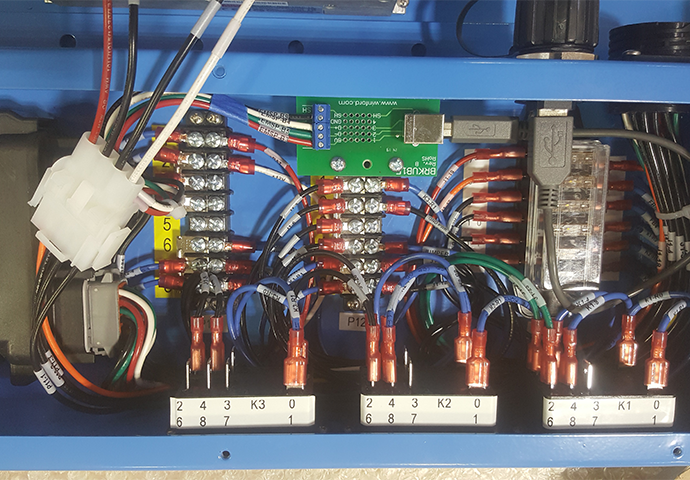

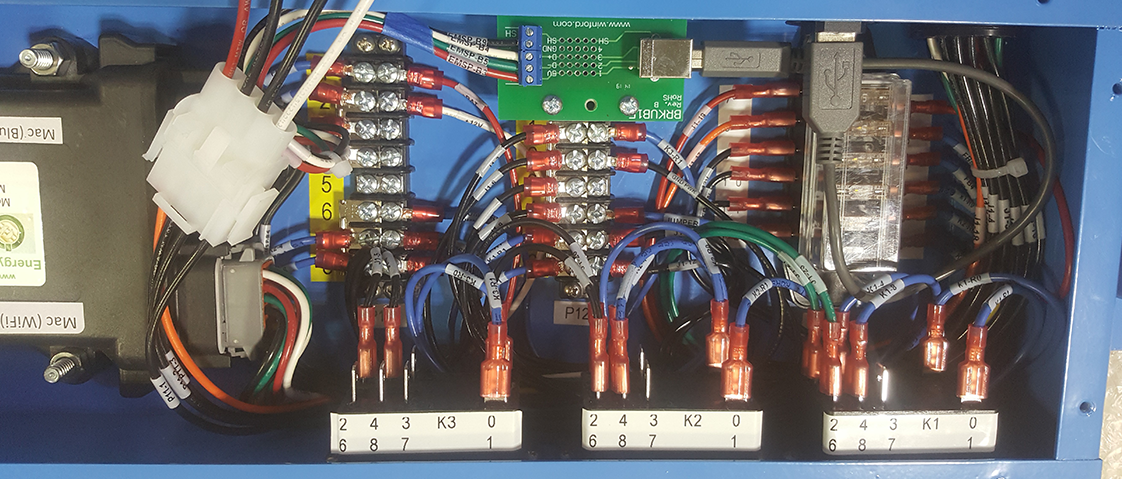

The customer sought MIS’ superior controls knowledge and UL pedigree to aid the UL accreditation process. Chiefly, our engineers went to work designing the proper custom enclosure for the client’s needs. Our designers built a three-piece custom control enclosure using PEM Fasteners. Overall, this move simplified a cost-effective assembly process. This enclosure included:

- Structuring the metal enclosure to be manufacturing friendly.

- Selecting UL components and documentation support of these products.

- Implementing a breakout board mounted on DIN rail. In effect, this process alleviated minimal diameter wiring issues.

- Coordinating with the receptacle manufacturer to cut to length and tag all wires with ferrules and ring terminals. In like manner, this move helped reduce assembly time.

- Providing solutions from prototype to manufacturing production with a complete turnkey application.

MIS Results

All in all, the result is an industrial control system that meets the size restrictions and UL acceptance. By and large, Anderson Material Handling relied on MIS Controls’ UL508A background and NEC adherence to create a control entity that passed the UL test and offers a cost-effective controls solution. On the whole, we are proud of our ability to service our client’s needs and offer them custom designs that resolve their current issues.

To learn more about MIS Controls, contact us. We look forward to hearing from you.