EV Battery Testing System

Challenge

Usually, industrial controls do not include integrating and assembling industrial control panels used for electric vehicle production. In this situation, this unique challenge allowed our engineers to problem solve many areas in the EV Battery field.

Application

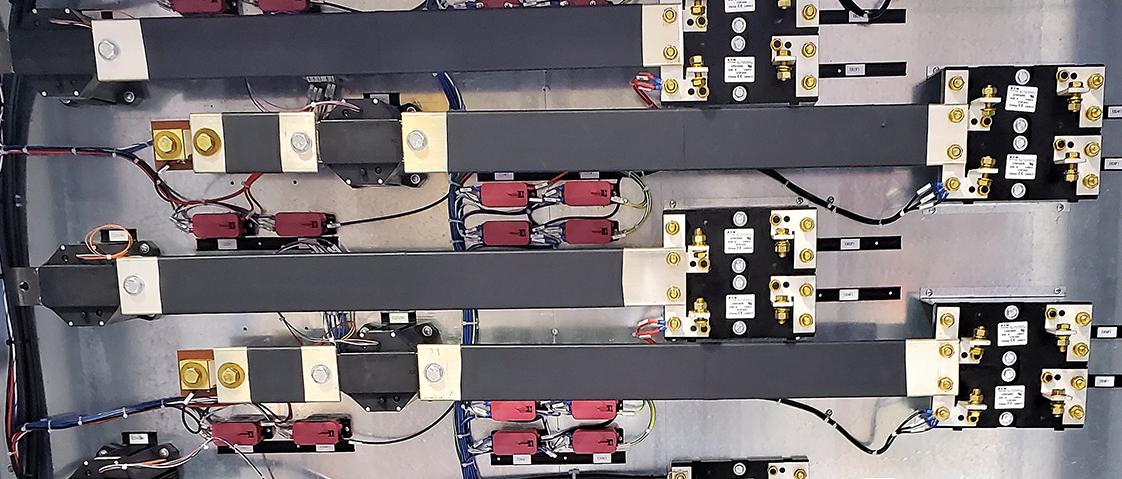

The 1000 VDC contactor is a definite purpose, single-pole, magnet-closed contactor designed explicitly for use in applications where a compact, heavy-duty device is essential but where interruption of heavy overload current is not required. Markedly, this customer had specific requirements for 1000 VDC contractors for high winds as needed for EV battery testing.

MIS Solution

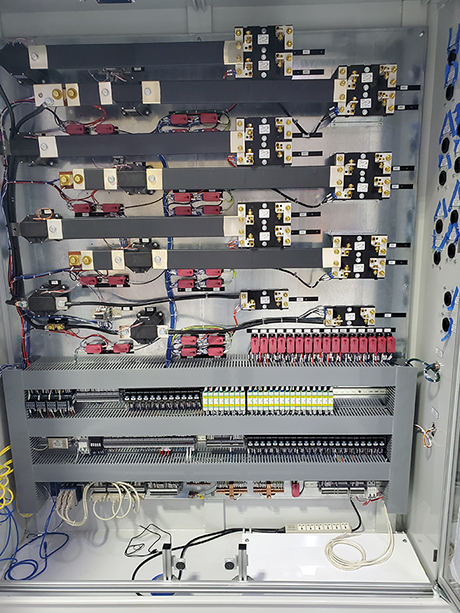

Most importantly, the MIS approach identifies the problem, assesses the needs, and proposes a solution. The process after that becomes simple, and it starts by assigning a champion to carry direct communication with the customer and meet all requirements and standards. In this case, customized solutions with parts made specifically to complete the application at hand. For this reason, our customization included:

- A custom copper bus bar to handle the high current as needed for the battery testing.

- Engineers highly regard these bus bars because of their flexibility, safety, and ability to reduce costs.

- A diesel locomotive wire with a very high strand count [DLO with over 500 strands employed].

- These cables transmit the power from the generator to the electric drive motor.

- Unique lugs were needed to be precisely crimped and properly torqued onto the wire.

- Custom brackets and supports elevate components to the same plane [height] on the sub-plate.

- Installing customized protective covers to avoid electric shock and installing safety measures—at MIS, safety is of utmost priority.

- We provide top safety initiatives to all of our jobs.

MIS Results

All in all, the results included efficiently solving electrical and mechanical challenges. Throughout the build, our engineers assembled an industrial control panel that meets all of the application requirements, customer specifications, and most importantly, all the NEC standards. Our customers have recognized MIS Controls as a solution provider and a leader in the industrial Control Panel and Enclosure Assembly field. We’re proud of our ability to service our client’s needs and offer them custom designs that resolve their current issues.

To learn more about MIS Controls, contact us. We look forward to hearing from you.