How to Improve Process Efficiency with Custom Control Panel Solutions

Take Back Control…Efficiently

Control panels are an integral part of many industrial and commercial processes. They are responsible for controlling and monitoring various aspects of a process, including electrical power distribution, temperature control, and safety systems. In order to ensure that processes run smoothly and efficiently, it is important to have a control panel that is designed and configured to meet specific needs and requirements. Custom control panel solutions offer numerous benefits for improving process efficiency, including increased automation, enhanced safety, and reduced downtime. In this article, we will discuss how to improve process efficiency with custom control panel solutions and provide tips for choosing the right control panel for your business.

Increased Automation

One of the biggest advantages of custom control panel solutions is the ability to automate various aspects of a process. Automation helps to eliminate manual intervention and reduces the risk of human error. This results in more consistent and reliable performance, and can also free up personnel to perform other tasks.

For example, custom control panels can be designed to automatically adjust temperature and pressure settings based on process requirements. This ensures that the process operates within specific parameters, reducing the risk of malfunctions and downtime.

Enhanced Safety

Custom control panel solutions also enhance safety by providing better monitoring and control over various aspects of a process. This can include implementing safety interlocks, automatic shut-off systems, and emergency stop buttons. These features help to reduce the risk of accidents and ensure that processes are operating within safe parameters at all times.

For example, a custom control panel for a chemical plant might include safety systems for controlling the flow of hazardous chemicals. This can help to prevent spills and leaks, which can have serious consequences for personnel and the environment.

Reduced Downtime

Custom control panels can also help to reduce downtime by providing early detection of potential problems and allowing for quick and efficient troubleshooting. This is achieved through advanced monitoring and control systems, which provide real-time data on the status of a process. This allows operators to quickly identify potential issues and take action to prevent downtime.

For example, a custom control panel for a manufacturing plant might include a monitoring system that alerts operators to potential equipment failures. This can help to prevent equipment breakdowns, reduce downtime, and minimize the impact on production.

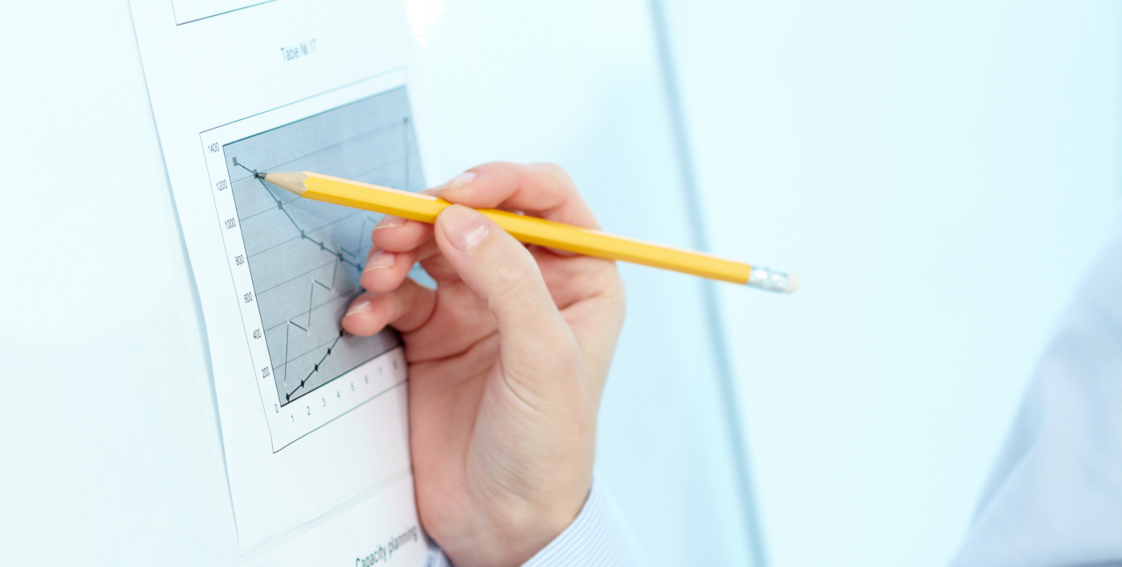

Choosing the Right Control Panel

When choosing a custom control panel solution, it is important to consider several key factors. These include:

1. Process Requirements:

Consider the specific needs of your process and ensure that the control panel solution is designed to meet those requirements.

2. User-Friendliness:

A control panel should be easy to use and understand, with clear and intuitive controls and displays.

3. Integration:

Consider how the control panel solution will integrate with existing equipment and systems.

4. Support and Service:

Choose a control panel provider that offers reliable support and service, and has a proven track record of delivering quality solutions.

In conclusion, custom control panel solutions are a powerful tool for improving process efficiency and enhancing safety. By automating various aspects of a process, reducing downtime, and providing better monitoring and control, custom control panels can help to optimize performance and achieve better results. When choosing a control panel solution, it is important to consider the specific needs of your process and choose a provider that offers reliable support and service.