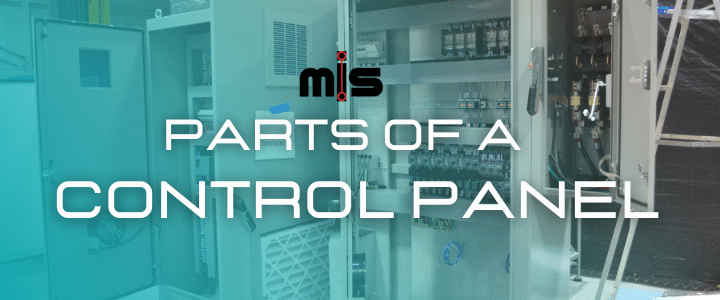

Five Parts of an Industrial Control Panel

In both assembly and function, an industrial control panel consists of specified processes and necessary parts. From the enclosure cabinet protecting internal electrical components to the machine screws holding everything together, each aspect harnesses the panel’s power. MIS Controls, Inc. holds various certifications, thus providing customers with a wide selection of assembly practices and standards. Overall, this blog outlines the parts of a panel and their purpose regarding function and application.

Enclosure Cabinet

The enclosure cabinet is the physical barrier protecting the internal electrical components from external impacts. Depending on the application and size specifications of the control panel, MIS can customize both shape and material. From stainless steel to aluminum, cabinets require different materials depending on the end environment and operation. Customers seeking specific industrial panel certifications may include varying enclosure cabinet requirements. For example, in the NEMA Enclosure Type Standards, the environment surrounding the cabinet must be rated and adjusted to meet the outlined control panel specifications.

Sub Plate

The subplate can be found within the enclosure cabinet assembled with various electrical and mechanical components. The purpose of the subplate is to ease the assembly of electrical devices and components specific to each project. The application and functionality of the industrial control panel determine the necessary components found within the subplate. The layout of the subplate may also provide flexibility as well as space to meet electronic manufacturing standards.

Mechanical Parts

A wide range of mechanical parts within the control panel establishes the most efficient and desired functionality. Typical parts include duct wire ways, screws, bolts, nuts, din rail, and rack units. During assembly, manufacturers install such parts through the placeholders or cutouts to successfully meet control panel interface requirements. Overall, mechanical wiring ensures additional effectivity guarantees within the entirety of the control panel.

Electrical Components

Electrical Components

The most prominent features of a control panel are the electrical components found throughout the entirety of the panel. Circuit breakers, fuses, relays, and disconnect switches are the most common parts found within almost every panel. However, with growing technology and advanced automation, electrical control panels may also hold various functionality-based electronic devices. From telecommunication functions to the ability to connect other support equipment, the manufacturing at MIS continues to integrate the latest cutting-edge technology.

Additional Equipment

Based on customization preferences and specifications, additional devices and equipment can enhance the operations for the given application. One example includes air conditioning units to regulate panel temperature or power suppliers mounted within the enclosure. Discussions between the customer and MIS determine the best additional components for any industry and application.

All in all, each part holds immense importance to the success of each control panel. The MIS Controls, Inc. process demonstrates the focus on proper assembly in all aspects of the panel. Whether it be the addition of climate regulation devices to sizing requirements for an enclosure cabinet, MIS continues to meet customer specifications with high-quality products. Request a quote today to learn more about how MIS can effectively manufacture all control panel needs!